Necessary Devices and Methods for Reliable Lead Infraction Clean-up

Addressing lead infractions properly demands an extensive strategy that blends the right devices with strategic methods. Simultaneously, the use of specialized clean-up devices, such as HEPA vacuums and lead-specific cleansing representatives, is vital for thorough pollutant elimination. Reliable containment techniques, consisting of plastic sheeting and unfavorable air stress systems, are crucial to avoid the spread of harmful products.

Personal Protective Devices

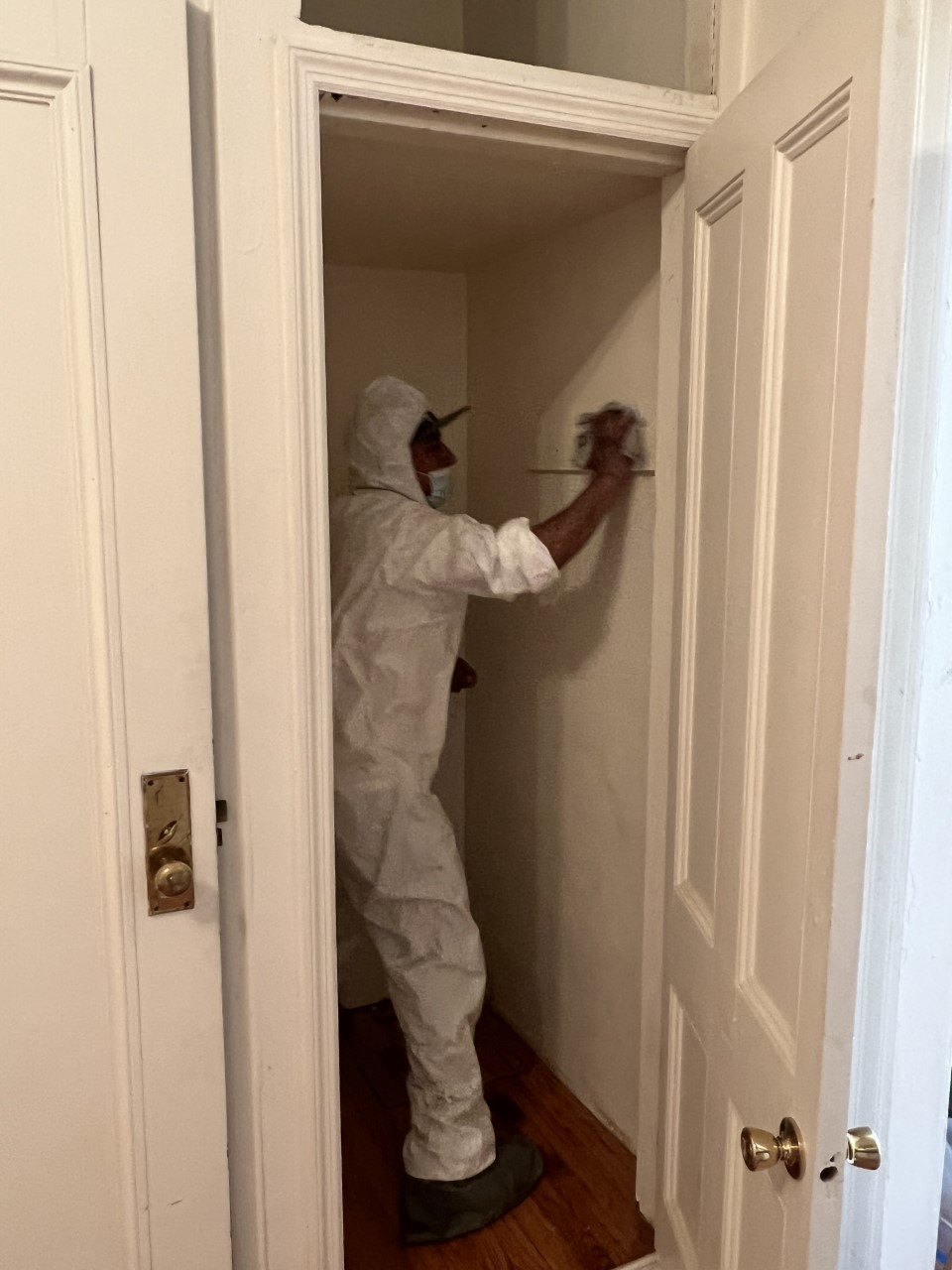

Individual protective tools (PPE) is an essential element in the effective management of lead contamination cleaning. The necessary PPE for lead cleaning includes respirators, safety clothing, gloves, and eye protection.

Respirators, particularly those equipped with HEPA filters, are crucial for filtering airborne lead fragments, avoiding breathing. Safety clothing, consisting of coveralls and disposable matches, stops lead dust from sticking to workers' garments, lowering the danger of second contamination.

Additionally, rigorous training on the proper usage and upkeep of PPE is vital. Employees should be educated on putting on and doffing treatments to prevent contamination. Normal evaluations and substitutes of PPE components are essential to maintain their safety capabilities, making sure a safe and compliant cleaning procedure.

Specialized Clean-up Devices

Another essential device is the wet/dry vacuum, which can properly clean up both dirt and liquid impurities. These vacuum cleaners typically feature HEPA filters to offer an extra layer of safety. Wet cleans or tack towels are also important for surface area cleansing; they are specifically created to record and hold lead particles, decreasing the danger of spreading out contamination.

For even more stubborn deposits, specialized lead-removal cleaner are needed. These representatives are created to damage down lead particles, making them simpler to eliminate. Scrub brushes with strong bristles can assist in this process, particularly on harsh surface areas where lead dirt often tends to stick extra strongly.

Additionally, encapsulants are used to seal lead-contaminated surfaces, avoiding the release of lead dust. These specialized paints and finishings are created to stick to different substratums, supplying a long-lasting option for lead control.

Efficient Containment Techniques

Efficient containment methods are essential in reducing the spread of lead contamination during cleanup tasks. Applying durable control techniques guarantees that lead particles do not migrate to untouched locations, consequently safeguarding both workers and the environment. One key approach is the usage of plastic sheeting to seal infected areas. Heavy-duty polyethylene barriers can be mounted from flooring to ceiling to create a regulated job area, considerably reducing the threat of air-borne lead dust dispersal.

To enhance control, encapsulants can be applied to surface areas that are not being eliminated or interrupted. These specialized finishes bind lead dust, lowering its accessibility for resuspension. Additionally, all employees should put on proper Personal Protective Tools (PPE), including respirators and non reusable fits, to avoid contamination spread.

Safe Disposal Practices

Making sure safe disposal methods is a crucial part in the management of lead contamination clean-up. Proper disposal alleviates the threat of lead returning to the setting and endangering public health and wellness. The very first step is to recognize and segregate lead-contaminated waste from other products. Secure containment making use of heavy-duty, leak-proof containers is necessary to prevent spillage throughout transportation.

Moving lead waste requires adherence to stringent guidelines. Utilizing qualified hazardous waste carriers guarantees that the products are managed sensibly. Documentation, consisting of shows up describing the kind and amount of waste, should accompany shipments to track the waste from the site of origin to its last disposal location.

Designated contaminated materials disposal facilities are equipped to handle lead-contaminated materials safely. These centers often employ innovative approaches such as stablizing, solidification, or chemical therapy to counteract the lead prior to disposal. Landfilling in specialized, lined areas that avoid leachate from contaminating groundwater is a common practice for last disposal.

Normal training for workers associated with lead garbage disposal is vital to keep safety and security criteria and protect against unexpected exposure. By adhering to these techniques, companies can substantially decrease the environmental and wellness effects associated with lead contamination.

Regulatory Conformity Tips

Sticking to regulative compliance is extremely important in More about the author the successful execution of lead contamination cleaning. Understanding and adhering to government, state, and local guidelines guarantees not just the security and health of people but likewise the legal and monetary well-being of the clean-up organization. The Epa (EPA) establishes stringent criteria, such as the Lead Remodelling, Fixing, and Painting (RRP) Regulation, which mandates appropriate qualification and training for professionals taking care of lead-based activities.

Compliance starts with a thorough evaluation of suitable regulations Lead Paint Removal Service and regulations. Organizations should remain upgraded on any kind of legislative changes, which can be helped with with normal training sessions and registering for industry updates. Documentation is one more important conformity facet; maintaining detailed records of all activities, including evaluation reports, worker training logs, and disposal materializes, is necessary.

In addition, involving with licensed lead assessors or take the navigate to these guys chance of assessors makes certain that lead hazards are correctly identified and mitigated. Companies have to apply making use of Individual Protective Equipment (PPE) and make sure that security procedures are purely adhered to. Finally, transparent communication with stakeholders, consisting of workers, clients, and governing bodies, will certainly promote a culture of compliance and accountability, ultimately adding to a more secure and more effective lead cleanup process.

Verdict

Efficient lead violation cleaning necessitates the integration of specialized tools and strategic methods to ensure security and efficiency. Personal protective tools (PPE) safeguards workers from exposure, while risk-free disposal techniques and strict adherence to regulative conformity are essential for properly handling unsafe waste.

Comments on “Specialist Lead Violation Removal in NYC-- Guard Versus Wellness Hazards”